What should we think about before deciding what DX means for the manufacturing industry?

The Corona disaster is said to have brought about a major change in corporate activities, but in reality, it is not a new major change, but rather a significant acceleration of the pace of change that was already occurring. It can be said that changes that would have taken several years to occur at the previous pace have been delayed by the corona disaster.

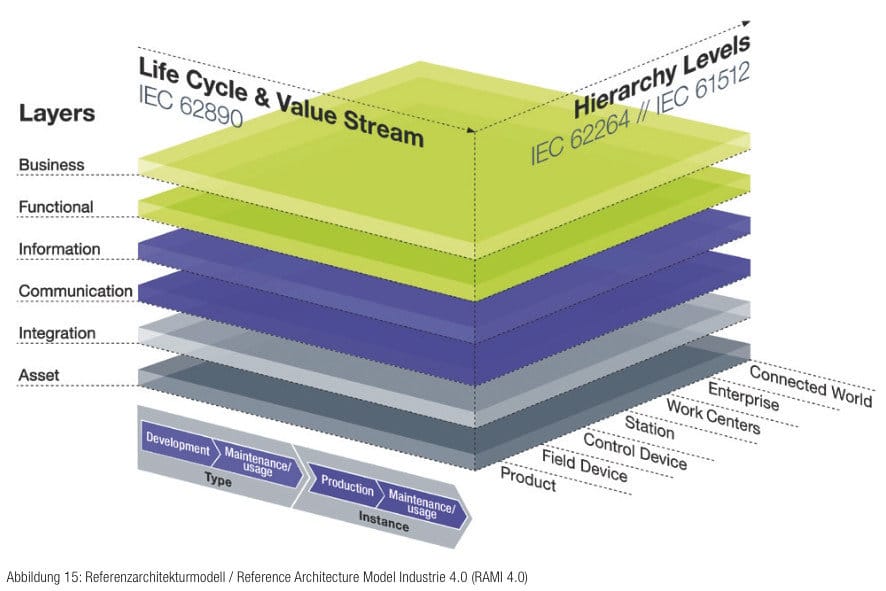

The manufacturing industry is no exception to this influence. In recent years, the key words surrounding the manufacturing industry have been “Industry 4.0,” “IoT” and “Smart Factory. Of course, these terms do not mean that they are no longer needed. Rather, they are required to be realized as soon as possible, and it can be said that the goal of manufacturing DX is to create an environment for their realization.

So, “What is Manufacturing DX and how does it work? Before answering the question, I would like to clarify the “deliverables” that manufacturers can gain by promoting DX. The two deliverables can be summarized as follows.

The first deliverable is a thorough improvement in operational efficiency. This isn’t just a story for the plant. We aim to increase the efficiency of the entire supply chain, including the customer and supplier communities.

The second deliverable is building an advantage in the competitive market. This is not just about improving product performance and quality. It’s about gathering and analyzing your product’s position in the target market, its market reputation in real time, and building an advantage over the competition, not just in terms of product performance and quality, but in terms of other factors as well.

These deliverables are commonplace and not particularly new to the manufacturing industry. However, while “supply chain management” and “integrated manufacturing and sales”, for example, are taken for granted with a clean slate, few have been able to build a satisfactory system in the real world.

The Significance of Small Starts and Future Scalability for DX

Let me tell you one more important thing. Your existing plant is running some kind of system – maybe a packaged system such as ERP, production management, MES, production scheduler, etc., or maybe it’s an application that you’ve been hand-assembling for 10 years or more. The larger the business, the larger the manufacturing company, the greater the scale of the business, the greater the variety of systems that exist, from the upper level mission-critical systems to the manufacturing floor level, and the more systems are interfaced to each other. On the other hand, in the case of smaller companies, although they have some sort of system, it is often seen that many operations are performed on behalf of the company using Excel. It is unreasonable to promote DX while ignoring the “reality of what is already working”.

Simply replacing the current system with the latest system is not enough to achieve the ideal of DX. In many cases, the “small start + future scalability” approach is used to avoid excessive IT investment, and this approach is the most appropriate for DX. A PDCA (Plan-Do-Check-Act) cycle based on the ROI (return on investment) is said to be the most effective way to establish a PDCA cycle:

Small IT investment → confirm the effect of the investment → investment effect → investment at the next level → expand the effect of the investment.

Here are three strategies that manufacturers should consider as a DX strategy.

With these assumptions in mind, we can finally think about the specifics of DX for manufacturing. In this article, I will outline the following three strategies for the DX strategy. I will provide more details in the next article.

1 – Platform Strategy

In the B2C world, platform strategies by U.S. Internet companies, such as GAFA (Google, Amazon.com, Facebook, Apple), have become widespread and have become one of the most effective ways to engage customers. So what is the appeal of a platform strategy for the manufacturing industry, which is a prime example of B2B?

In a nutshell, it is the construction of an “ecosystem” that utilizes a platform. The idea of an ecosystem is not to connect individual systems through system integration, but to allow customers to freely select and operate systems provided by multiple vendors on the same platform. It may be easy to understand the concept if you imagine an expanded version of ERP that consists of multiple modules. How to realize the construction of such an “ecosystem” is one of the points of DX, and it is an area that must be considered as a strategy.

2 – Cloud Application Utilization Strategy

As with platform strategies, this is another one that is well established in the world of B2C applications. The “service model” and “subscription model” have been established as common billing systems for video distribution services and games, while the traditional “on-premise model” (i.e., purchase of software licensing rights) is the majority of B2B applications, with the exception of a few accounting systems and customer management systems. This is due to the reality that the options for cloud applications are limited at the moment.

However, we can expect this situation to change as more and more business applications are provided in the cloud. There is no doubt that “service models” will become mainstream in business applications, and it is necessary to think about how to utilize them.

3 – 360-Degree Vision Strategy

Most of the traditional mechanisms for manufacturing companies to use digital technology are designed to control and provide visibility into the operations within the plant. However, actual manufacturing activities cannot be carried out by ignoring the “linkages” with external communities, such as managing change points in orders with customers, purchasing with suppliers, and subcontract management. With the exception of a few large manufacturing companies, the majority of external community relations are now handled by email, telephone and fax. These are definitely “points that need to be improved”. I believe that it is necessary to think about the role of the systems of each department and company in an inclusive manner and create a new system to reduce the waste that has been caused by forcing the systems to work together as an individual.

In this article, we have outlined the three strategies and the assumptions that manufacturers need to make when thinking about DX strategies. In the next article, we will discuss the “platform strategy” in more detail. The major package vendors in the U.S. and Europe are uniformly aiming to become platformers. We are also seeing B2C platforms starting to offer their services to B2B customers. In the world of business applications, we may see two levels of competition, first between platforms, and then between products within platforms. This is the kind of situation I intend to introduce in this series of articles.

Meet the Author

Takumi Kurita

Director of Rootstock Japan K.K.

https://www.linkedin.com/in/takumi-kurita-8060a331/