Engineering Change Management Software

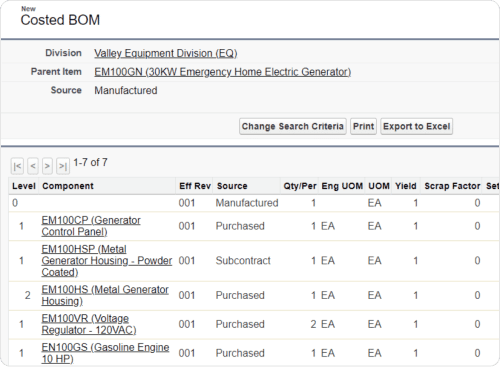

With Rootstock’s engineering change management software, easily create and manage BOMs, ensure production accuracy, and track detailed costs.

With Rootstock’s engineering change management software, easily create and manage BOMs, ensure production accuracy, and track detailed costs.

“The advantages to the company and to the employees are clear to everyone. The reaction has been, ‘Gee, why didn’t we do this sooner.’”

“With the push of a button we can create a sales order and a project in Rootstock that goes on to build sub-projects, ties in the Bill of Materials and creates the project budget. Worktime has been saved and numerous mistakes have been avoided thanks to this ‘magic button.’”

“BOM Maintenance is a beautiful thing. We can copy, clone, and maintain our BOMs much more efficiently than we could before Rootstock.”

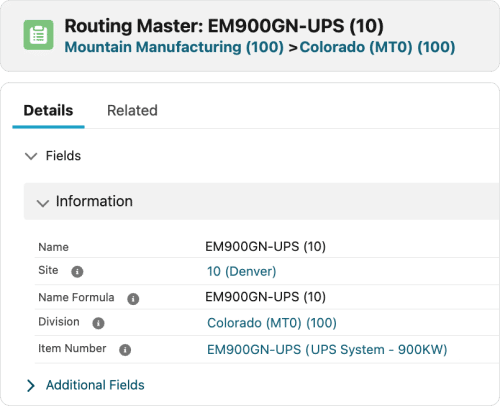

Stop using spreadsheets and fighting to reduce revision errors. Switch to a more efficient, cloud-based engineering change management software. Rootstock gives engineering teams complete control of drawings, engineering changes, bills of materials, routings, costs, and more.