Manufacturing Inventory Software

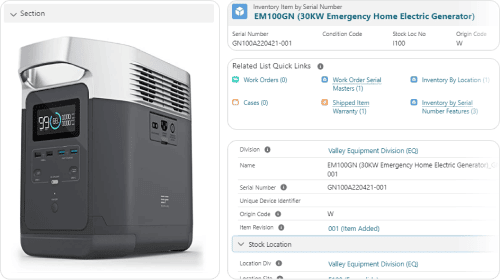

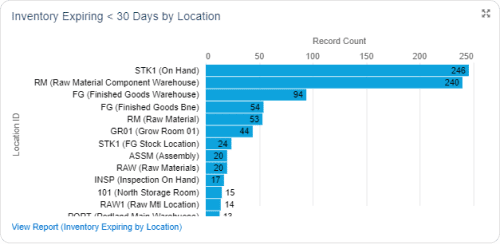

Precisely manage inventory and costs in real-time and across multiple locations all from any device with Rootstock Manufacturing Inventory Software.

Precisely manage inventory and costs in real-time and across multiple locations all from any device with Rootstock Manufacturing Inventory Software.

“Rootstock provides the functionality we never had before, which is a dynamic, detailed look at inventory, cost of sales, and sales. It gives us a real-time ability to dissect pretty much anything we want. It’s a big benefit.”

“We had no visibility to see how demand was interconnected at a part level. Rootstock helped us connect the sources of demand and increase our production efficiency.”

Our cloud-based ERP and manufacturing inventory management system gives you the insights to minimize inventory costs, keep production running smoothly, and ensure customer orders are fulfilled on time. With purpose-built inventory management software designed by and for manufacturers, you can make better decisions faster and with fewer errors.