Why Choose Rootstock Manufacturing Production Software

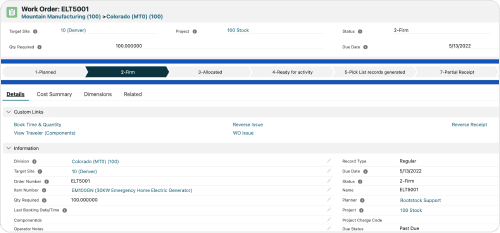

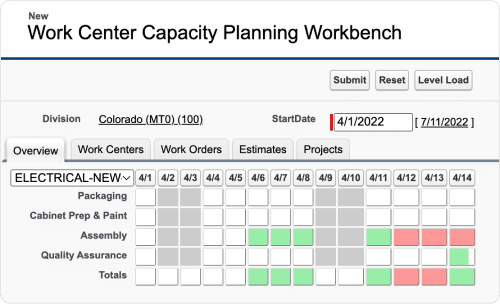

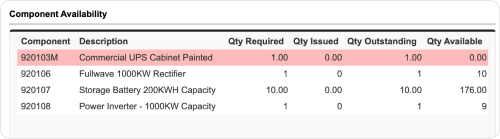

When combined with Salesforce Manufacturing Cloud, Rootstock Cloud ERP offers manufacturers, distributors, and supply chain businesses a single platform on which to grow and manage your operations. Rootstock Production ERP System lets you control and automate your production process, reduce the risk of human error, increase productivity, and reduce downtime. With a production planning and scheduling software such as this, you can:

- Gain a Competitive Edge with a Flexible, Customizable Production ERP: Easily deploy an ERP application tailored for your company, working precisely for your unique needs, using intuitive, low-code technology.

- Improve Collaboration Internally and With Customers and Suppliers: Stay in close contact with key stakeholders using features like embedded social media and custom portals, and stay in the loop from any mobile device, anywhere in the world.

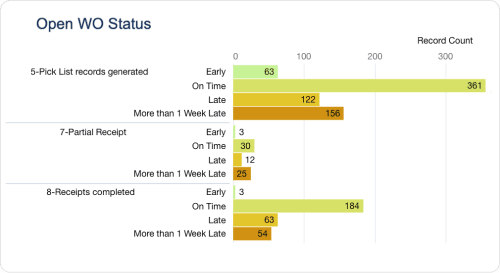

- Better Guide Production with Advanced Analytics & Reporting: Use advanced analytics and artificial intelligence to spot patterns and trends, make better decisions, and stay ahead of shifting trends.

- Control Quality and Maintain Compliance: Seamlessly integrate with ComplianceQuest EQMS and other compliance apps on the Salesforce Platform to exceed customers’ quality expectations and stay compliant with rules and regulations.