How Rootstock Software helped one small manufacturing firm replace manual, spreadsheet-heavy processes with Cloud ERP automation

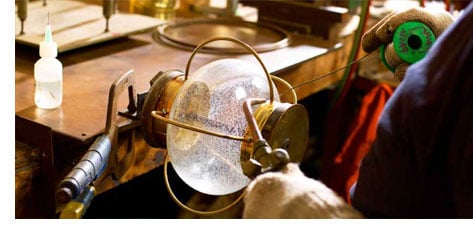

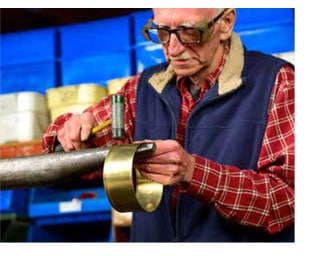

Since 1987, Northeast Lantern has been manufacturing and selling handcrafted, solid brass and copper lighting fixtures. Like many similar small manufacturers, Northeast Lantern relied on too many spreadsheets to manage the business.

Every bit of data was entered and stored on Excel spreadsheets that didn’t link to each other.

However, as Northeast Lantern grew to become a 3.5-million-dollar company, all those spreadsheets created more problems than solutions. With no formal system for inventory or engineering and no single database, the company knew that further growth would require a modern ERP solution.

Northeast Lantern selected Rootstock Cloud ERP to give the company visibility into all of their data and to automate production processes that used to be performed manually.

About Northeast Lantern

Northeast Lantern augments their standard fixtures with custom lighting fixtures, as over 20% of their products are customized pieces.

To maintain the high quality of their handcrafted products, Northeast Lantern employs skilled craftsmen who use original manufacturing methods. According to Product Development Engineer Steven Plante, “We do a lot of our production on old machines, so we don’t have the latest and greatest machining, CNC-type machines. We do things manually.”

Spreadsheets, Spreadsheets and More Spreadsheets

While traditional manufacturing methods allow Northeast Lantern to continue to provide high-quality, handcrafted lighting, old data and system management methods proved to be an increasing obstacle to growth. In fact, the company had no formal system at all. With so much customization and so many parts to build and maintain in inventory, the company didn’t have a firm grasp on engineering and inventory control, and reporting was limited.

Engineering – A Spreadsheet for Every Item

Northeast Lantern managed all their engineering records in Excel spreadsheets. Operations Manager, Dustin Almon explains:

“We had a spreadsheet for every item that we kept track of, with individual BOMs on that spreadsheet,” he says. “For example, if one part was used on multiple BOMs, it was on every spreadsheet, but there was no real connection. If we needed four parts for one SKU and four for another SKU, we would need to make eight. We had no visibility to see how demand was interconnected at a part level, so we would end up making them in two different batches. Rootstock helped us connect the sources of demand and increase our production efficiency.”

Further complicating the process were incorrect and missing part numbers and out-of-date BOMs.

They knew that managing engineering documents using spreadsheets was an impediment to growth.

No Inventory Control

The company also had no system to control inventory and no cycle counting program. “We had no control over our inventory because we didn’t know at any one time what we had in inventory for a specific part, finished good or subassembly,” says Plante.

Northeast Lantern knew they needed a modern system to help them gain control over their inventory.

Reporting

Spreadsheets also figured prominently in reporting. According to Almon, “We had some Excel spreadsheets, and we copied and pasted from that to generate performance reports, including on-time delivery and production stats.”

This very manual task of reporting critical business information was time-consuming and inefficient. Northeast Lantern needed the reporting capabilities of a modern software solution.

We had no visibility to see how demand was interconnected at a part level. Rootstock helped us connect the sources of demand and increase our production efficiency.

– DUSTIN ALMON, OPERATIONS MANAGER

Choosing Rootstock Cloud ERP

Northeast Lantern began their search for a modern solution with a consultant, who quickly helped them decide that a cloud-based ERP system offered the best solution. They liked the idea that they could access the system and their data anywhere in the world in a web browser and, as a small manufacturer, they really liked that onsite hardware investment was minimized.

Most importantly, they wanted to abandon their spreadsheet-heavy manual processes. The company was looking for a system to help them plan production and catalog all items into a single database. They wanted to see the connections between the parts and where they would be used and get control of inventory and production efficiencies.

Northeast Lantern ultimately chose Rootstock Cloud ERP. In addition to increasing visibility and automating manual processes, Rootstock had several advantages:

- MRP – Northeast Lantern did their due diligence, investigating the calculation behind Rootstock’s They found it “highly configurable,” so they could make it work the way they needed.

- Sandbox – Rootstock’s sandbox would allow Northeast Lantern to test changes before going live with them.

- QuickBooks integration – Northeast Lantern plans to use QuickBooks for its financials, and Rootstock can integrate with that solution.

- Salesforce Platform – The fact that Rootstock runs native on the Salesforce Cloud Platform was an important factor in the selection process, and the company likes the potential to integrate with other apps available on the Salesforce.

Implementation

The combination of no database, over 25,000 individual SKUs and limited resources slowed the implementation process. Despite the delays required to address these issues, the implementation was ultimately a success.

We had some Excel spreadsheets, and we copied and pasted from that to generate performance reports, including on-time delivery and production stats.

– STEVEN PLANTE, PRODUCT DEVELOPMENT ENGINEER

Preparing the Data

“For us, it was getting the data into the right format to be able to use that data. We had a lot of part numbers that were missing, parts that didn’t have numbers, obsolete part numbers and incomplete BOMs, so we had all that in front of us, and we also had to get the data in the right format.”

The company did a lot of copying and pasting from their Excel spreadsheets, checking, double-checking, and triple-checking to make sure they weren’t putting bad data into the system.

Once they completed that difficult task, the data load was “relatively painless,” according to Heal. But all that work would pay off in the long run. By focusing on data preparation before loading that data into Rootstock, Northeast Lantern ensured that once their new system was up and running, they would be confident in the accuracy of their data.

Developing a Hybrid Manufacturing Model

The company also spent a considerable amount of time trying different business models to fit their production methodology. Rootstock’s flexibility and customizability turned out to be a key differentiator for Northeast Lantern.

According to Dustin Almon, the company originally used a production model based on batches.

“When I started here, we made things in batches. We’d make a batch and put it on the shelf and then use it in a kind of make-to- stock environment,” he says. “We transitioned to a make-to-order environment. Then, when we were considering Rootstock, we looked at keeping that strict one-to-one, make-to-order model or transitioning to a make-to-stock/assemble-to-order hybrid model with inventory at select points.”

Northeast Lantern finally settled on a subassembly/finished goods model in which inventory would be controlled at the subassembly level, and then final production would be based on that subassembly inventory.

One of the biggest obstacles to overcome was the sheer number of SKUs. As Chris Heal explains, “For a given product, there could be up to 100 different permutations: the type of glass, the type of material we make it out of, what color we finish it in. It took us quite a while to get our heads around a model that would work for that.” The company eventually decided to maintain a unique SKU for every one of those products.

For a given product, there could be up to 100 different permutations. That was one of the biggest challenges that we had.

– CHRIS HEAL, PRESIDENT

Using Rootstock Cloud ERP

Northeast Lantern currently makes daily use of several Rootstock Cloud ERP modules, including engineering, shop floor, summary-by-item-in- detail review in the forecasting MRP, scheduling and capacity planning, inventory transaction management, purchasing, requisitions, work orders, and sales order processes. These modules have automated processes that used to be manual and time-consuming.

For shop floor workers and customer service reps (who have less responsibility or administrative privileges), Northeast Lantern has tailored their views so that they only see sales order and customer service processes.

Benefits of Rootstock

The most valuable benefits of running Rootstock Cloud ERP have been increased visibility into their data and the automation of formerly manual processes.

A Single Database

“The 50,000-foot view is that, for once, we have all of our information in a single database,” says Plante. “There are a lot of intangibles that we take for granted now. We can look up a part number and see all the places it’s being used and how much we’ve consumed. Just the fact that we have all this information at our fingertips is invaluable.”

“In addition,” adds Plante, “we now have part numbers and BOMs for our entire product line. We have inventory locations and control, work order tracking, prioritization of work and the ability to track labor and inventory costs.”

Increased Visibility

“For example,” says Plante, “in May of 2019, we started using the clock on/off feature to track labor costs and have begun to accumulate data to improve the accuracy of our standard operation times.

Updating these times will allow us to improve our capacity planning in the future.”

Dashboards

Northeast Lantern also likes the dashboard and reporting features of Rootstock. “We are increasing our use of dashboards and the graphical displays that are available, and we are presenting that information,” reports Dustin Almon. “We recently started sharing one of the dashboards in the break room so the employees can see orders that are scheduled that week, what has already been shipped, any overdue orders, and work orders completed by week.”

Employee Reactions

Northeast Lantern employs both older and younger workers. While the younger workers have embraced Rootstock Cloud ERP as just another part of doing their jobs, it took a little longer and a little more training for the older workers to adapt. The company says that everyone views the new system as a positive improvement.

The company’s Customer Service department has been especially receptive to using Rootstock. Says Plante, “If you go down to customer service, they’re probably going to tell you how much they love it, because it puts everything in one spot.” Before Rootstock, Northeast Lantern customer service reps had to hop back and forth to find information in emails and manual Accounts Payable files. Now, these reps can access important customer and service information on a single screen.

The most valuable benefits of running Rootstock Cloud ERP have been increased visibility into their data and the automation of formerly manual processes.

Connecting with the Rootstock Community

For Northeast Lantern, the Rootstock Community is a key resource. “I do like the potential of the new Rootstock Community. It’s going to play a crucial role in our use of Rootstock,” says Almon. “It’s a good resource to see who’s doing what because the system is so customizable, and it’s helpful to see how other people are using certain features.”

If you go down to customer service, they’re probably going to tell you how much they love it, because it puts everything in one spot.

– STEVEN PLANTE, PRODUCT DEVELOPMENT ENGINEER

Summary

There is no doubt that Rootstock Cloud ERP has helped Northeast Lantern abandon management by spreadsheet in favor of a more customizable, more efficient and less costly solution.

Northeast Lantern is planning to expand their use of Rootstock in the future to other areas as well.

“The more we use the system, the more familiar we become with the available features,” explains Plante. “As we become more familiar, we are looking to become more sophisticated in how we use the system.”

We recently started sharing one of the dashboards in the break room so the employees can see orders that are scheduled that week, what has already been shipped, any overdue orders, and work orders completed by week.

– DUSTIN ALMON, OPERATIONS MANAGER

Download the Case Study

Click here to download the Rootstock Software Case Study “Northeast Lantern: From Spreadsheets to Cloud ERP.”

About Northeast Lantern

Northeast Lantern exists to provide high quality solid brass and copper lighting fixtures through highly skilled and dedicated employees, excellent customer service and proficient manufacturing processes. Northeast Lantern offers a lifetime guarantee and unique ability to customize any fixtures to ensure confidence and satisfaction with customers. Northeast Lantern continually innovates and improves American made lighting fixtures to maintain a competitive edge in the industry and keep up with market demands. Over 20% of the company’s lanterns are custom. Northeast Lantern sells their finely crafted products through a network of US and Canadian authorized dealers.

To learn more about the Northeast Lantern, please visit northeastlantern.com.