Topics of interest

The only thing you can always count on in product development is change. Engineers will continue to change and improve a product design until it is done–or they run out of time. Updating dimensions or tolerances for manufacturability, only for the wrong revision to be sent to a customer and returned for rework. Changes for manufacturers are becoming far more expensive and disruptive as manufacturing processes becomes more complex, projects more bespoke, and customers more demanding. While changes to designs, materials, and processes are a fact of life for manufacturers, the additional costs in terms of delays, downtime, and lost opportunity can quickly erode margins as well as employee morale and customer satisfaction. A recent Air Force Institute of Technology (AFIT) study determined that the net cost of engineering change orders (ECOs) for their projects far surpassed the 15% typically factored into the bids. In fact, they found that the final cost for major projects with engineering changes exceeded the initial estimate by 72%, whereas jobs with no changes only increased by 11%.

The increasing urgency for manufacturers to manage change more efficiently and effectively has elevated the importance of change management across the industry. Builders have been managing change since the first Giza stones were slid across the Sahara, but digital transformation and the increasing complexity that comes along with it have left many manufacturers and their manual change management tools behind. New times call for new tools and methods to make change and associated growth successful.

Manufacturers today have a wide range of change management tools, technology, and methodologies available to them. However, not all are created equal; only a few truly provide the needed power, visibility, control, and access. In the following paragraphs, we’ll look at the most effective and how they help manufacturers adapt to changing circumstances, improve efficiency, and reduce the risk of project failure. Before we do, let’s first review what exactly engineering change management involves and the risks and challenges manufacturers encounter while implementing it.

What Is Engineering Change Management?

Engineering change management is a universal concept that can mean different things in different industries. For those in the manufacturing sector, it defines the processes by which teams intake, analyze, document, and finally implement the change requests that surface during the product lifecycle. In today’s connected, digital world, where information is widely distributed and feedback immediate, a change request can come anywhere, any time. Maybe a first article inspection surfaces a manufacturing defect that needs to be redesigned or retooled. It could come from an unexpected material substitution due to a supply chain shortage. Or in heavily regulated industries, such as medical devices, it might result from a CAPA investigation.

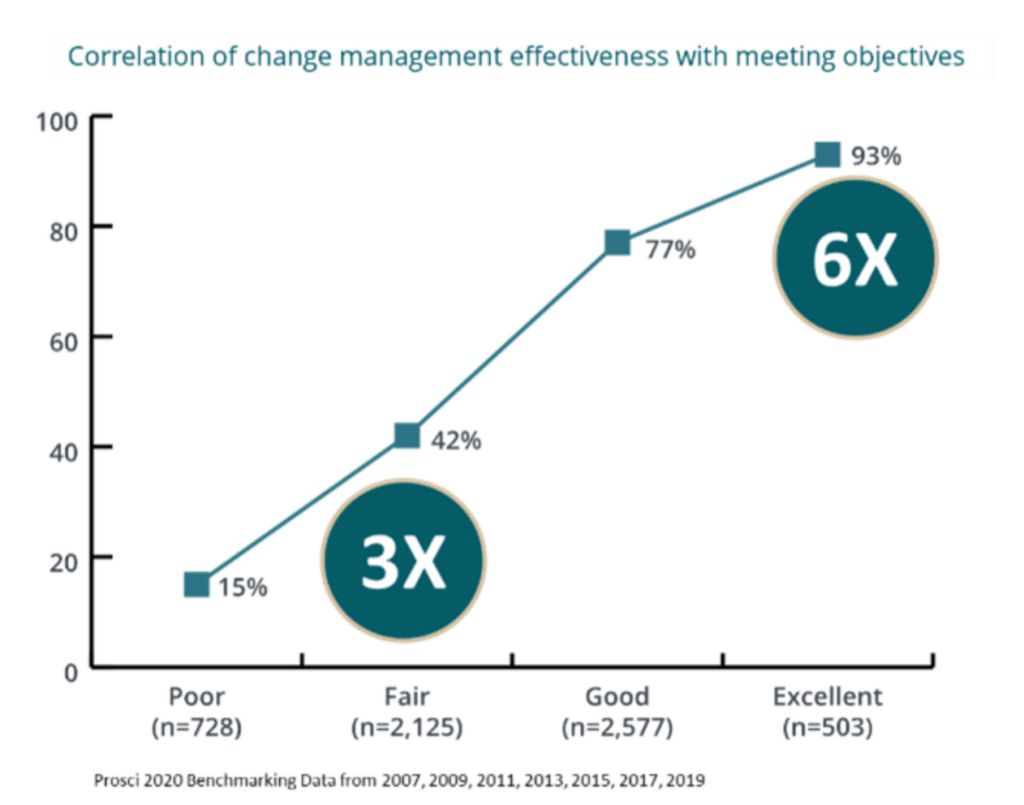

Whatever the cause, the change will immediately impact your operations. Even the most minor request can significantly affect quality, timelines, scope, cost, and even safety. The ripple effect of a change is unknown until it is thoroughly investigated and analyzed. For example, a change in materials or a part, while seemingly a one-for-one swap, may require additional study, analysis, or even regulatory approval. This could seriously impact the production schedule and delivery. Underscoring the point is recent research showing that “initiatives with excellent change management are six times more likely to meet objectives.” That’s why it’s crucial for manufacturers to put in place a well-defined and repeatable system and process for handling change requests, no matter how insignificant on the surface.

Engineering Change Management Processes & Best Practices

Whatever the scope, every engineering change management process begins with a change request. Whether submitted by design, production, or quality assurance, the request is usually codified in an engineering change request (ECR) document. The ECR should then trigger a review and analysis by the team or engineering change control board (CCB) responsible for the project. If approved, an engineering change order (ECO) is created. The ECO is the master project file and should include everything involved with the change, from a listing of materials or parts to be exchanged to the affected processes and related documentation and information needed to inform and complete the order. Effectivity needs to be considered when the change should be implemented in production.

It is best practice not to mix revisions within a production run or customer order so the change is trackable after shipment. Next is notification, which is crucial to eliminate any confusion and frustration within the project team and ensure that the change is implemented and progresses in the order and manner documented by the ECO. A detailed evaluation and analysis should follow the implementation once completed. As with any analysis, selecting the correct key performance indicators (KPIs) to measure and analyze is critical. It will allow you to not only assess the impact and effectiveness of the change but your overall ECO process.

The importance of the CCB to the successful outcome of any change request cannot be overstated. Ideally, the board will be assembled before the start of any project and will include a cross-section of key individuals from inside and outside of the company, like project managers, engineers, other stakeholders (e.g., sales and finance business leaders, etc.), suppliers, and even customers. The board’s charter and operating procedures must be clearly defined at the outset, with well-defined roles and dotted lines for decision-makers. To be proactive, the CCB should meet regularly to surface and discuss any potential changes that might affect the project. An inclusive membership ensures the input and perspective of each impacted team or stakeholder are considered and that surprises–and frustrations and resistance that come along with them–are kept to a minimum.

Change Management Tools and Techniques

Engineering change management’s value for manufacturers has not been lost on software providers, and today’s builders have numerous market solutions to choose from. While some overlap exists, the typical point solutions generally fall within the following categories:

Change order management

Change order management is typically included in manufacturing software from product lifecycle management (PLM) to manufacturing execution software (MES) and enterprise resource planning (ERP) solutions, and typically comes with a tools that allow project managers and stakeholders to track, document, communicate, and manage the process from start to finish.

Decision analysis matrix

Unlike the point solutions, a decision matrix usually comes included as part of a business intelligence (BI) or productivity tool or is something that can be configured as part of your ERP. Decision matrices organize the options in tables or quadrants and assign weights that help teams prioritize and determine where to focus.

Configuration management

Change can be especially challenging to manage for highly configured products. When products have many options that can be included, each configured bill-of-materials (BOM) must be revised individually and the product history must be accurate for each configured product that is in use with customers. Configuration management tools can help manufacturing teams control and manage changes to project documentation, software, and hardware changes throughout the process including serialization when serialized components are revised.

How Engineering Change Management Software Overcomes Challenges

At a bare minimum, an effective engineering change management program should have some combination of the above capabilities. To overcome change management challenges it is critical to help build teams analyze their options, monitor configuration changes, and manage the change order process from beginning to end. The legacy approach has been to stitch a collection of those point solutions together. However, digitization and the increasing complexity of today’s production lifecycle require greater integration and automation than those point-to-point solutions typically provide, exposing manufacturers to additional risk and cost. The more comprehensive approach involves the use of ERP change management software that is the system of record for manufacturing documentation.

An ERP engineering change management solution provides the CCB with complete visibility into every project facet. With ERP change management software, project managers, can easily create, maintain, and track multi-level BOMs, manage revisions, and calculate and control costs from one application. While each company and request is unique, every project manager would agree that the biggest challenge with any change is keeping track of and providing visibility into all the documentation, reviews, and approvals that are part of an ECO. A manufacturing ERP solution like Rootstock eliminates many of the manual tasks and associated risks involved with changes and gives the CCB and production team the visibility and control needed to complete the project with as little disruption and additional cost as possible.

Schedule a demo today to learn more and see how Rootstock’s ERP change management software can transform your engineering change process.